If you would also like to read about steel tube bending procedures, We have now it protected in addition to tube bending machinery.

Generally speaking, putting bends proper future to each other really should be prevented if in any way feasible. If bends usually are not sufficiently spaced out, it could be quite challenging to suit sections which have been now bent about the die.

Electricity effectiveness. Metal roofs replicate the suns UV and infrared light-weight rays that add to roof surface radiant heat, which can result in a ten-25% reduction in cooling expenditures.

A small bend at the end of a big section could bring on challenges It is best to omit compact flanges with big and large areas.

This rule states that the higher the elongation worth (the broader the selection amongst produce and tensile toughness), the higher the forming capacity on the alloy.

Some great benefits of rotary bending contain building constant, extensive bends with regular and exact Proportions. Rotary bending is suitable for manufacturing profiles and shapes with intricate cross-sections. However, rotary bending necessitates specialized tools and tooling.

These radius instruments are incredibly useful for smaller and medium-sized press brakes, which have tables that are way too modest to mount the large dies essential to get hold of huge radius bends.

Mainly because corrugated metal panels are connected with Countless fasteners, They might be destroyed by overtight or unfastened fasteners. Inappropriate installation can result in probable leaks and water injury. Fasteners can also loosen or corrode as time passes, requiring additional repairs.

Combining the aesthetic look and suppress charm of standard shingles, website clay tile, cedar shake, and slate with each of the efficiency great things about metal, these devices are a well-liked option for homeowners seeking a rapidly, simple, and affordable roofing Option that simulates the appearance of other roofing materials.

Notice this is just a guideline. Finding the real minimum amount bend radius for steel or aluminum plate demands a small exploration.

When bending a workpiece, it will Obviously spring back somewhat once the load is lifted. Thus, it should be compensated for when bending. The workpiece is bent past the expected angle, so it takes the desired form just after springback.

A plate’s grain route emanates from the mill’s rolling approach, which stretches the metallurgical structure and inclusions of the material. The grains run parallel to the rolling route.

In the majority of options, countersinks are additional to sheet metal components utilizing hand tools. For this reason, it’s important to keep in mind that countersinks needs to be no further than sixty% with the sheet metal thickness.

Reduction cuts are important for blocking bulging and even tearing at bends. Relief Minimize widths must be equal or larger in comparison to the sheet metal thickness. Moreover, the length of relief cuts should be now not than the bend radius.

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Shane West Then & Now!

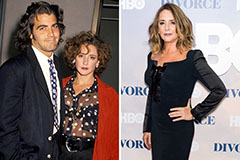

Shane West Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now!